- Home Page

- Company Profile

-

Our Products

- Dust Collector

- Dust Collection System

- Compact Dust Collector

- Portable Dust Collection Unit

- Multiple Bag Dust Collector

- Panel Saw Dust Collector

- Cartridge Dust Collector

- Portable Dust Collector

- Dust Collecting Equipment

- Woodworking Dust Collector

- Sanding Dust Collector

- Vertical Bag Dust Collector

- Dust Control Equipment

- Single Phase Vertical Bag Dust Collector

- Air Blower

- Fume Extractor

- Solder Fume Extractor

- Portable Fume Extraction Unit

- Portable Fume Extractor

- Laser Fume Extractor

- Soldering Fume Extractor

- Portable Fume Extractor With Flexible Hose

- Portable Welding Fume Extractor With Suction Arm

- Smoke Extractor

- Welding Fume Extractor

- Mobile Fume Extractor

- Portable Welding Fume Extractor

- Portable Fume Extractor Unit

- Industrial Fume Extractor

- Centrifugal Fan

- Single Inlet Centrifugal Fan

- Centrifugal Air Fan

- Centrifugal Duct Fan

- Inline Centrifugal Fans

- PP Centrifugal Fan

- Cabinet Centrifugal Fan

- Centrifugal Belt Drive Fan

- Portable Centrifugal Fan

- Direct Drive Centrifugal Fan

- Electric Centrifugal Fan

- High Speed Centrifugal Fan

- DIDW Centrifugal Fan

- Belt Driven Centrifugal Fan

- High Pressure Centrifugal Fan

- Direct Drive Centrifugal Fans

- Axial Flow Fan

- Blower Fan

- Cooling Fans

- Man Coolers

- Exhaust Fan

- Centrifugal Blowers

- Curved Impeller

- Industrial Blowers

- Axial Fans

- Ventilation Fan

- Inline Cabinet Fan

- Bifurcated Fans

- Duct Fans

- Cabinet Inline Fan

- Degasser Blower

- Turbo Blowers

- Blower Wheel

- Air Pollution Control Device

- Smoke Filtration System

- Induced Draft Fan

- Suction Blower

- Dust Collector

- More Info.

- Contact Us

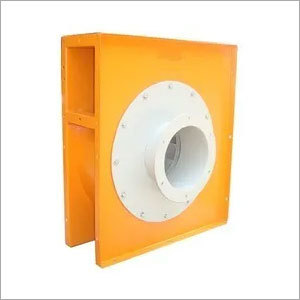

Cabinet Centrifugal Fan

12000 INR/Unit

Product Details:

- Blade Material Aluminium

- Size 24

- Type Cabinet Centrifugal Fan

- Installation Type Duct Mounted/Free Standing

- Power 0.25 HP Horsepower (HP)

- Power Source Electric

- Voltage 220-240 V Volt (v)

- Click to View more

X

Cabinet Centrifugal Fan Price And Quantity

- 12000 INR/Unit

- 1 Unit

Cabinet Centrifugal Fan Product Specifications

- 355 mm Millimeter (mm)

- Grey

- 4 Star

- Double Inlet Double Width Impeller

- Galvanized Steel

- Single

- 24

- 0.25 HP Horsepower (HP)

- Cabinet Centrifugal Fan

- Electric

- 220-240 V Volt (v)

- No

- Duct Mounted/Free Standing

- Aluminium

Cabinet Centrifugal Fan Trade Information

- 15 Unit Per Day

- 2-3 Days

Product Description

Controlled by AC power, this Cabinet Centrifugal Fan is available in free standing design. Widely used as part of central air conditioning unit, this fan has extensive applications in commercial and industrial buildings. The housing part of this fan is made of standard grade steel or galvanized steel plate. Available with single layered or double layered plate design option, this centrifugal fan uses taper sleeve type bearings with mechanical alignment facility. Tempered and quenched steel made blades of this fan ensure its high speed operation. The motor of this fan has been made as per global standards.

Cabinet Centrifugal Fan Features:

- Galvanized steel impeller of this fan reduces noise level.

- Copper wire equipped motor

- Energy efficient operation

- Long working life

Cabinet Centrifugal Fan Specifications:

- Dimensions: 225 x 144 mm

- Bearing system: 2-ball bearing

- Rated voltage: 115V AC, 50/60 Hz

- Operating voltage: 92-138V AC

- Starting voltage: 92V AC

- Input current: 1.25 A

- Input power: 108 W

Superior Ventilation Performance

Equipped with a double inlet double width impeller and a high-efficiency motor, this centrifugal fan ensures robust air movement, making it ideal for large spaces needing consistent ventilation. The device is tailored for air handling units and versatile HVAC applications, providing air flow rates between 1200 and 3600 m/h.

Durability and Reliability

Constructed from galvanized steel with a galvanized iron frame, the fan excels in corrosion resistance and structural integrity. Its IP54 protection guarantees resilience against dust and splashes, ensuring stable long-term operation in tough industrial or commercial environments.

Optimized For Quiet Operation

Thanks to its advanced design, the fan maintains noise levels below 70 dB, safeguarding the comfort of occupants even during extended periods of use. This makes it suitable for locations where minimal noise pollution is crucial, such as offices or healthcare facilities.

FAQs of Cabinet Centrifugal Fan:

Q: How do I install the Cabinet Centrifugal Fan in my HVAC system?

A: You can install this centrifugal fan via duct mounting or as a free-standing unit. Its designed for seamless integration with air handling units and HVAC setups, and should be fixed securely within the cabinet structure, following the manufacturers guidelines and adhering to local electrical standards.Q: What makes the TEFC motor advantageous for ventilation applications?

A: The TEFC (Totally Enclosed Fan Cooled) motor prevents dust, moisture, and contaminants from entering, greatly extending the motors lifespan and reducing maintenance requirementscritical for demanding ventilation and air handling applications.Q: When should I use a Cabinet Centrifugal Fan with this air flow capacity?

A: This fan, with its 12003600 m/h air flow range, is well-suited for medium to large commercial and industrial spaces where robust, consistent air circulation is essentialsuch as factories, office buildings, or hospitals.Q: Where can the Cabinet Centrifugal Fan be mounted?

A: The unit supports both duct-mounted and free-standing installation options. Its design is optimized for cabinet mounting, but it can be positioned wherever effective ventilation is required, provided that electrical connections and airflow pathways are established accordingly.Q: What is the energy efficiency rating of this fan, and what does it mean for usage?

A: With a 4-star energy efficiency rating, the fan reduces overall energy consumption while delivering high-performance ventilation. This makes it a cost-effective choice in scenarios where extended operation is expected, contributing to lower utility expenses and sustainable practices.Q: How does the IP54 protection class benefit the operation process?

A: IP54 ensures protection against limited dust ingress and water splashes, making the fan suitable for challenging environments where exposure to such elements is likely. This added protection increases operational reliability and safety.Q: What are the main benefits of using an aluminium blade with double inlet double width impeller?

A: Aluminium blades contribute to lighter weight and improved corrosion resistance, while the double inlet double width impeller enhances air handling capacity and efficiency, resulting in optimized airflow and quieter performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS